The operation of a double diaphragm pump, or pneumatic diaphragm pump, is both simple and effective: they are pneumatic pumps suitable for transferring fluids with reciprocating motion.

The pneumatic diaphragm pumps are equipped with two opposing pumping chambers, hermetically divided into two, one in contact with the compressed air and the other in contact with the pumped fluid.

The diaphragms, placed between two pumping chambers and activated by the pneumatic motor, and the valves, designed to ensure the total passage of the fluid both inlet and outlet, are the only parts in contact with the fluid.

Air operated double diaphragm pumps, or air operated diaphragm pumps, are designed and manufactured to pump a wide range of fluids even with high viscosities and with suspended solids.

They can also be used for heavy-duty applications such as environments with high humidity or potentially explosive atmospheres thanks to the ATEX Directive with which they are equipped.

Unlike other types of pumps, the diaphragm pump for liquids has no limits of use, also adapting to dry operations, to mix fluids, in self-priming and submerged.

Years of experience make Fluimac the ideal choice as a partner for your business. As all operators in the sector know, there are many needs that require the safe use of a diaphragm pump, also called pneumatic double diaphragm pump, diaphragm pump or air pump. From the chemical sector and pharmaceutical to food

diaphragm pumps are used in many processes that need to transfer liquids; even in the presence of an environment made aggressive by the saturation of chemical products. Fluimac has in its catalog a wide range of pneumatic pumps to meet the needs of any type of processing.

The diaphragm pump

It is the ideal type of pump for moving dirty fluids with very high apparent viscosities and also with suspended solid parts. The construction method of these pumps gives them stability and safety, ensuring safe operation without the need for lubricated air. The processing speed can be adjusted, as can the capacity of

draft for unprecedented versatility of use. The quality of the materials used in the construction of the various models of Fluimac diaphragm pumps makes the pneumatic diaphragm pumps suitable and certified for use in hazardous areas and highly saturated with products

aggressive:

A type of diaphragm pump for every process

By relying on Fluimac in choosing a double diaphragm pump model, you will have the certainty of being able to work in complete safety. Guaranteeing the quality and the correct and prolonged operation of the double diaphragm pneumatic pump, in order to be able to maintain the production standards of your company high.

| PUMP TYPE | AODD | CENTRIFUGAL | LOBE | GEAR | SCREW | PERISTALIC | PISTON |

|---|---|---|---|---|---|---|---|

|  |  |  |  |  |  | |

| Variable Flow & Head Control | |||||||

| Deadhead Safoly | |||||||

| Dry-Running | |||||||

| Dry Solf-Priming | |||||||

| No Mechanical Alignment | |||||||

| No Eloctrical installation | |||||||

| Portability | |||||||

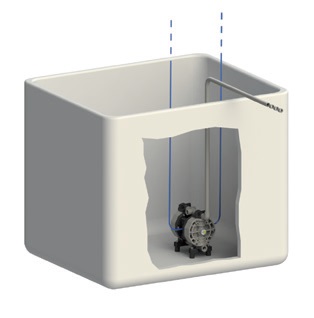

| Submorsible | |||||||

| Scalloss | |||||||

| Cavitation Tolerance | |||||||

| Low Shear & Degradation |

= Suitable = Limitations = Not Recommended

|  |  |  |  |  |  |

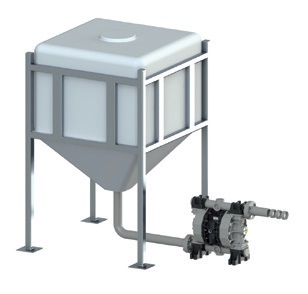

| Pump installed below head (positive suction) | self priming pump installed above head (negative suction) | Pump installed above drum or tank | pump installed on hopper for high viscosity liquid | Submerged pump | Suspended | pump installed on a mobile unit |

|---|---|---|---|---|---|---|

| when it is necessary to empty completely the container | Pump initially works with dr column without problem | with special featuring pump | hopper's height treat the fluid. Air pressure has to be high. Suction tube has to be bigger than pump's size. | it is necessary to check the chemical compatibility | Special version with flooring feet also in the upper part for ceiling fixing | with a trolley of cart when pump must be often moved |

Are you interested in Fluimac services?

Fulfil the below form and we'll reply as soon as possible.