Each centrifugal pump has its own characteristic curve, which is the graphical representation of the pump's performance.

- On the x-axis (horizontal axis) is reported the flow rate Q, usually in m3/h. It indicates the amount of fluid that passes through each section of the centrifugal pump over a defined period. This quantity depends on the dimensional characteristics of the pump, the number of motor revolutions (i.e., the speed of rotation of the impeller), and the characteristics of the fluid (density and viscosity depending on the temperature). The flow rate affects all the performances of the centrifugal pump and is the first technical parameter to consider.

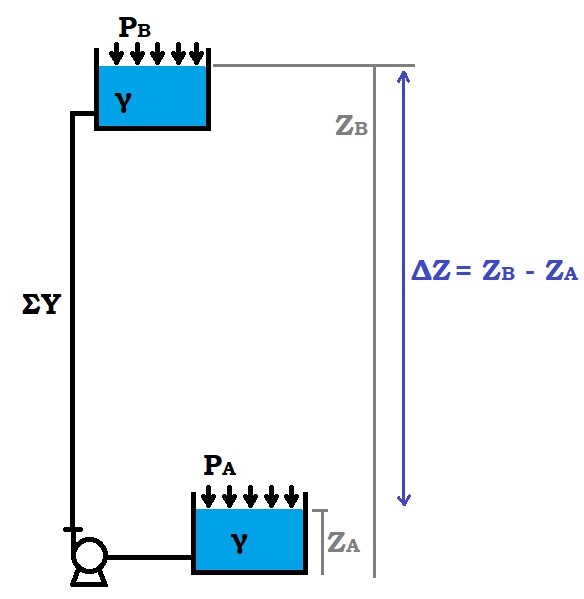

- On the y-axis (vertical axis) is instead reported the head H, usually in meters. It is calculated from the pressure difference between the outlet and the inlet of the centrifugal pump and represents how far the fluid can be pushed if it encounters resistance along its path, such as height, curves, or valves.