Choosing the material for the diaphragm pump is crucial to ensure adequate performance for the system, guarantee safety for operators and the environment, protection of the pump itself, and the chemical and temperature compatibility of the liquid with the construction materials.

The materials differ based on the pump bodies with manifolds, diaphragms, non-return valves with their balls, and gaskets.

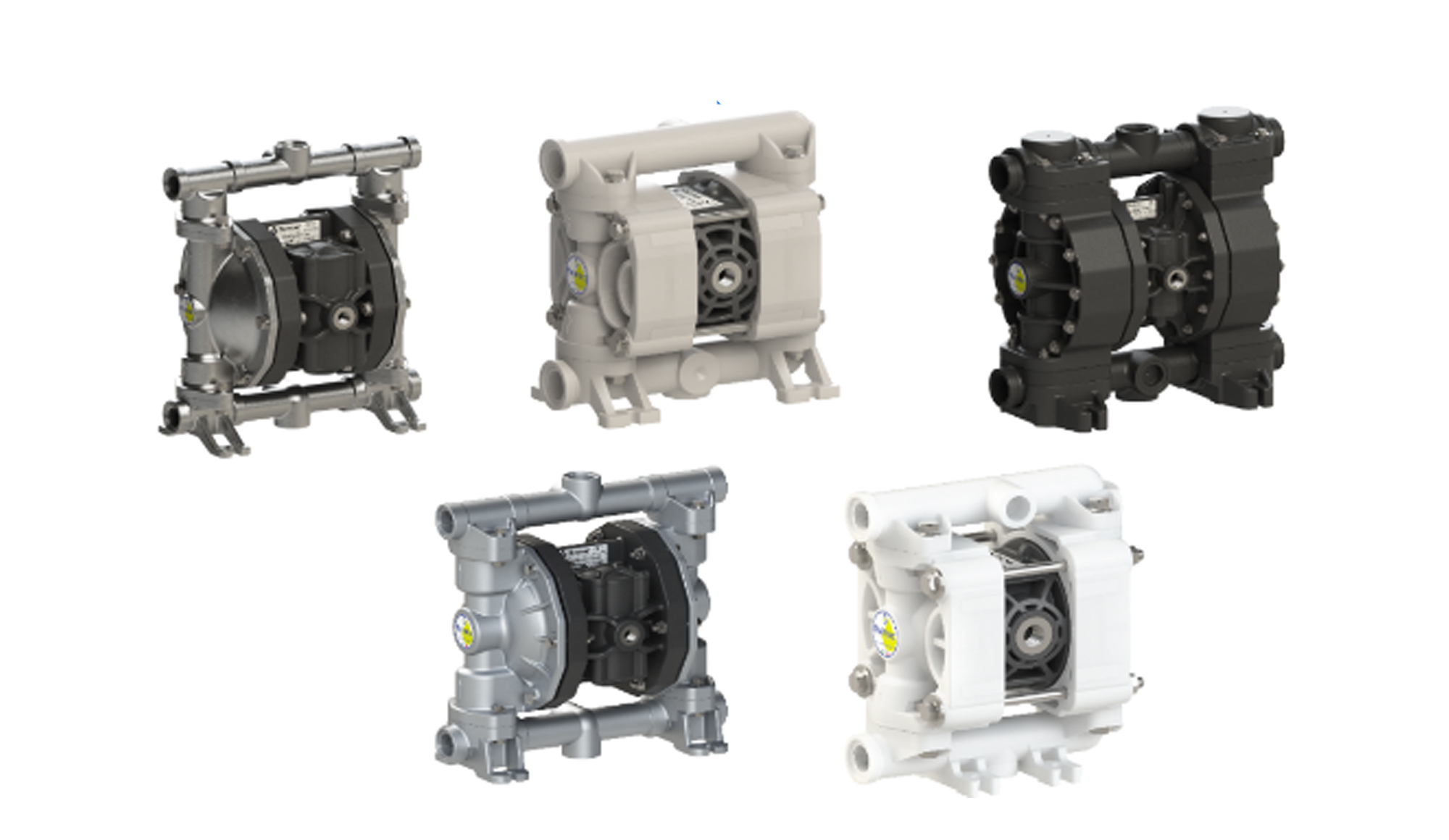

- Double diaphragm pump with components in POLYPROPYLENE (PP) for general use, where broad chemical compatibility is required. There is a conductive version for ATEX environments;

- Double diaphragm pump with components in PVDF where high chemical resistance to acids and high temperatures is required. Conductive version for ATEX environments;

- Double diaphragm pump with components in ACETAL (POMC) or ALUMINUM for pumping solvents and hydrocarbons or where good abrasion resistance is required;

- Double diaphragm pump in AISI 316 for excellent corrosion and abrasion resistance, or AISI 316 ELECTROPOLISHED for FOOD applications;

Diaphragms, balls, and gaskets:

- NBR is suitable for oil-based fluids, petroleum, water, hydrocarbons, and all mild chemicals. It has fairly common use;

- EPDM for alkaline solutions, diluted acids, ketones, and alcohols, as well as applications with abrasive liquids;

- PTFE has broad chemical compatibility as well as high corrosion resistance and non-stick properties. It is well suited for high-temperature applications;

- Diaphragms in HYTREL have good resistance to low temperatures and abrasion. They have fairly common use;

- Diaphragms in SANTOPRENE are ideal for solutions and diluted acids;

- Balls in AISI if excellent abrasion and corrosion resistance is needed or for very viscous liquids;

- Gaskets in VITON have good resistance to heat, aggressive chemical agents, and hydrocarbons. They are among the most used for diaphragm pumps in general applications.